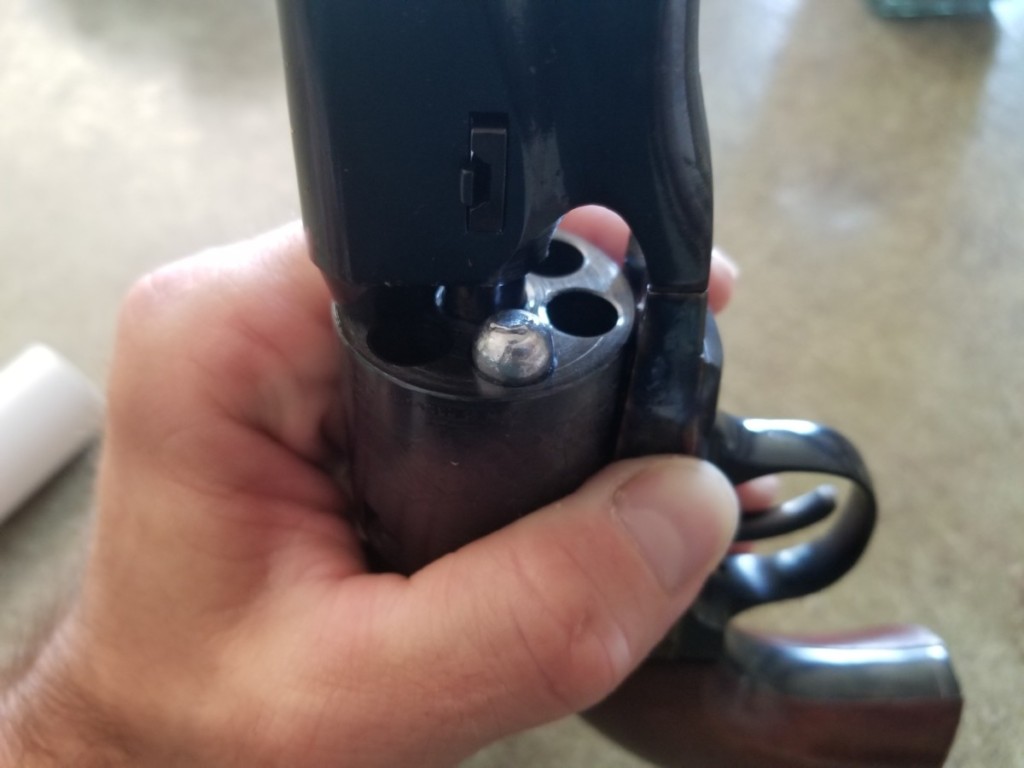

The first time you go to load a cap and ball revolver, you might notice that when you press down on the loading lever that thin ring of lead will appear above the loaded round ball.

This ring can easily removed, but is it normal? Does this mean that the round ball is too tight in the cylinder?

A shaved lead ring cut from the round ball when loading a black powder revolver ensures a perfectly sealed chamber and will help prevent dangerous chain firing. It is essential to see this shaved lead ring from each loaded round ball for your safety and those around you.

Let’s quickly cover why you get a lead ring when using the loading lever, what chain firing is, what to do if you don’t see a lead ring, and what to do if your round ball doesn’t load.

Why There a Lead Ring When Loading a Cap and Ball Revolver

Each of the 6 chambers in your revolver’s cylinders will be a particular diameter, .36″ for example for a .36 caliber model like the one in the photos.

The soft, lead round balls that I am using are .38″ which makes them 0.02″ larger than the hole they are trying to fit into. When pressed down by the loading lever, the lead will be softer than the steel of the cylinder and a uniform ring with 0.01″ thick wall will ideally be cut as the ball is seated.

Seeing this lead ring is the most critically important step you can take to prevent dangerous chain-firing when loading a black powder revolver and you should ensure that you witness it upon each and every round ball that is loaded into the cylinder.

What is Chain-Firing?

Chain firing is when a single round is intentionally fired from a black powder revolver but the burning powder of that shot makes makes contact with the black powder in neighboring chambers and sets them off as well. The gun can be destroyed and the shooter injured or worse.

Chain firing can occur for a few reasons, but the most common one is using round balls that are too small or the same diameter as your revolver’s chambers in the cylinder.

If a round ball is too small, it will have air gaps where hot gasses and burning powder can enter as they bypass the forcing cone that joins your cylinder to the barrel. If burning powder can get by your round ball, it will discharge that round immediately despite it not being aligned with the barrel.

This can absolutely destroy your revolver and even cause injuries or worse.

Chain firing can also occur if you have a light main spring, too wide of nipples, loose fitting caps, or any combination thereof.

As a round discharges, gasses will naturally try to escape the nipple hole as well. If the main spring is too light, the gasses will push back excessively on the hammer and it can allow burnt powder to blow back. If you have loose fitting caps, one may fall off and invite that burning powder into the nipple hole.

Never rely on greased cylinders or greased wads as a means to stop chain fire. They can help but are intended for lubrication. A shaved ring of lead upon each and every load is the number one thing you can do for safety!

What if You Don’t See a Lead Ring?

Ideally, if you were to use a new batch of round balls and you didn’t see a lead ring, you should stop immediately after that load. Firing it will be fine, though accuracy might be a bit off from ideal depending on the distance.

With only one chamber in the cylinder loaded, it won’t pose any threat to chain firing.

Now, if you have already loaded all five or six cylinders, I would recommend removing all of the caps from the nipples and removing the cylinder itself. Remove all of the nipples and pour the powder out through the hole where the nipples screw in.

The powder may likely be packed together too tightly to simply pour out and you can use a tooth pick or a piece of copper wire (anything non ferrous to avoid a spark) to loosen it up to pour out.

Next, take a small 3/16″ hardwood dowel (I used a stem from the top of a cattail plant) or brass punch and place the cylinder on a piece of pine board with a hole drilled through that is larger than the size of the round ball.

Place the cylinder over the hole that you will be working on and use a hammer to gently punch the round ball out. If using wood, make sure it is as short as possible to avoid breaking it from too much leverage.

If you insist on using a nail to do this, you risk damaging the threads of for the nipples. If you’re going to proceed anyway, make sure to use a syringe to squirt some water in the nipple holes to wet any powder that didn’t fall out in case you get a static spark.

I’ve also read that some people remove the cylinder, the caps, the nipples, the powder and then drill a small pilot hole in the round ball from the front and then screw a drywall screw into it for a few twists. Once that’s done that use pliers to pull it out.

I personally find the punch method the easiest.

Afterwards, do not continue to shoot with that batch of round balls unless you load and fire them one at a time.

I find it best to use 0.38″ round balls with a .36 caliber revolver, and a 0.454″ round balls for .44 caliber revolvers. Regardless of the size, as long as you see a complete lead ring after loading, you’ll go a long way in preventing a dangerous accident.

What if the Round Ball Won’t Load?

If you’re using an appropriately sized round ball for your revolver and it just won’t load despite how much you push on the loading lever, then it’s time to stop trying to load it.

Lead needs to be soft and in a near “pure” state in order to be loaded correctly on a cap and ball revolver. It it’s too hard, then it can damage your loading lever before you’ll ever get it seated.

You likely have a harder lead alloy — especially if you cast your own from scrap lead.

You can always melt down these round balls in smaller amounts with pure, soft lead in order to use them, or you can melt them into an appropriate size to use in a muzzle loading rifle or musket.

Check this out for the best sources of lead for casting your own round balls if you’re interested in increasing your self-sufficiency!