Chain-fire with a cap and ball, or percussion, revolver is when you pull the hammer back, squeeze the trigger, and all or additional chambers in the cylinder discharge along with the one that you intended to fire. Usually it happens in rapid succession and is a very scary experience.

A chain-fire can cause no damage at all, it can damage the revolver (often blowing off the loading lever and hitting the barrel wedge), or it can even hurt the operator.

It’s not something to be taken lightly, and every effort should be made to prevent such a thing from happening.

Let’s quickly talk about two of the most commonly held beliefs about why chain-fire occurs, a reason I’ve never heard anyone talk about before that I came across, and what you can do to fix it if you’ve got this problem as well.

Two Commonly Held Beliefs of How Chain-Fire Originates and How to Fix

The two most repeated reasons for why chain-fire occurs is due to an issue at the front and at the rear of the cylinder.

The first commonly held belief is that when you fire your intended chamber, the flame from that burning black powder will flare out slightly between the cylinder and the forcing cone of the barrel assembly. This flame will come into contact with crushed powder residue that is on the neighboring chambers and ride that faint trail of powder, bypass the projectile, and ignite the powder behind the projectile.

The commonly held belief for fixing this is to always make sure you cut a ring of lead as you seat a projectile into each and every chamber, and to use a grease agent over the round-ball or bullet in order to stop any flame from affecting it.

The second commonly held belief is that when you discharge your intended chamber, there is blowback that occurs as the burning powder sends most of its force down range, some of it will actually push back through the vent hole of the cone (or nipple) and that flame could enter into a neighboring cone or nipple.

The fix for this is to make sure that you have properly sized caps that have a very firm friction fit with the cone (or nipple). I personally like SlixShot nipples, and they work great with both CCI #11 and Remington #10 caps.

An Additional Reason for Chain-Fire (Manufacturer Defect) and How to Fix

Now I stumbled upon this reason that sort of falls in line with the first one we discussed above, but I’ve never heard anyone talk about the origin of the problem.

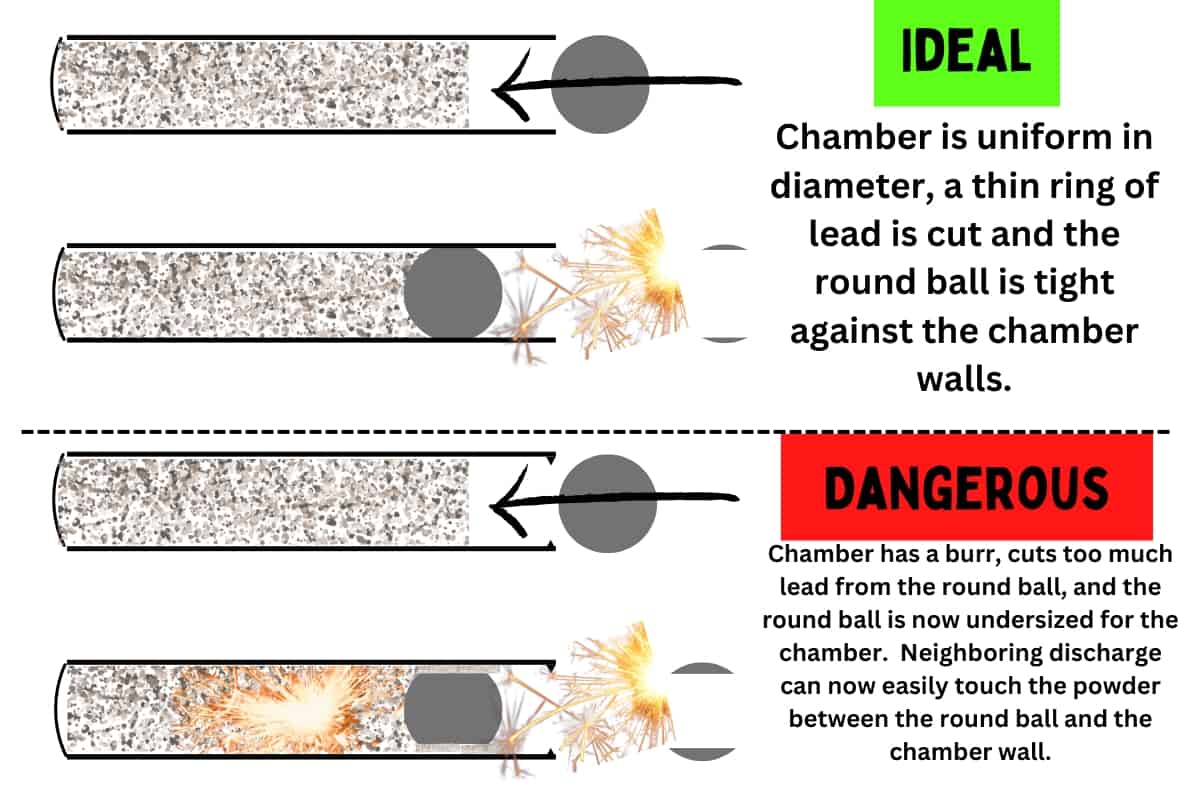

It’s almost preached in the black powder revolver community that you need to ensure that when you seat a round-ball, that you should see a ring of lead being cut as the slightly over-sized round ball is forced into the chambers of the cylinder. Since lead is softer than steel, the outer ring of the lead round ball will be cut away as the loading lever forces it in.

If you get a ring of lead, your chamber is perfectly sealed!… or so you thought.

You see, when you load that round ball and get that ring of lead, it operates under the assumption that the manufacturer has everything in perfect specifications and tolerances. It assumes that the outer edge of the chamber’s diameter is uniform and the same as any point within that same cylinder.

This is not necessarily true.

Both of my Uberti models were perfect, but my Pietta had an issue with 5 out of the 6 chambers. On these chambers, the outer edge of the chambers was slightly undersized when compared to the rest of their corresponding chambers due to the manufacturer leaving a burr that would overhang 5 of the 6 chamber entrances.

The burr made the chambers slightly more restricted than they already were, and the lead projectile would shave itself on that burr. Once it was forced past the burr, it was then undersized for the chamber. See the diagram below if this doesn’t make sense.

Even though I cut a ring of lead and should have (in theory) a perfect seal, I could actually see daylight around the round ball and if I gently shook the revolver the round balls would work their way forward and even stick out of the chamber halfway.

In order to fix this problem, I bought a small grinding stone for a hand-held rotary tool and placed it in my drill press. I saturated the griding stone with oil and set the drill press to its lowest setting. I would then hold the cylinder securely against the base plate below the grinding stone and do a few dry runs with the drill press off to ensure that when it was lowered that it would contact the edges of the chamber evenly.

Once I was satisfied, I gently lowered the drill press for a half second onto the affected chambers.

Afterward, I reloaded the revolver without powder and with the cones (nipples) removed and verified that I could not see daylight and I could not cause them to move when shaking the revolver.