The appeal of black powder revolvers is the ability to easily cast your own bullets. All you need is a mold, a dipper, something in which to melt the lead, and of course — lead.

One of the common things that come to mind are the lead wheel weights that you find on tires for balancing.

Newer wheel weights are made of steel and zinc and cannot be melted and cast for casting round balls. Older wheel weights are a lead alloy and can damage a black powder revolver’s loading lever but are still suitable for rifles and muskets.

Below we’ll look at the problem with wheel weights as a source for black powder revolvers, how to tell if the lead you have is suitable for your revolver, and what sources are ideal when looking for scrap lead.

Let’s get into it!

The Problem with Wheel Weights for Black Powder Revolvers

The EPA and other governmental agencies have weighed in (no pun intended) on the matter and deemed lead wheel weights an environmental concern. This is great for the environment when proper measures for disposal are not followed, but it’s definitely bad for those of us in the black powder community.

The days when we could befriend a local mechanic and pick up a few buckets of scrap wheel weights is fading as the lead alloy weights are replaced with steel and zinc — not round ball material.

Even if we were to get a bucket of lead-alloy wheel weights, we’re still not in the clear and have usable material if we are shooting black powder revolvers.

An alloy simply means that a given “metal” is actually a blend of several metals. Wheel weights are not pure, soft lead. They are a blend and that usually includes antimony and tin.

This isn’t a problem so much with long guns like muskets and black powder rifles because they are usually made slightly smaller than the diameter of the bore and are rammed down with a patch to fill the space.

With a cap and ball revolver, it is imperative to see a lead ring after you ram the round ball into the cylinder. This is to prevent chain fire which can cause the revolver’s cylinder to explode as multiple rounds discharge after firing one round. Not a fun occurrence!

To have the lead ring after loading each round ball, it necessarily means that you must use a very slightly over-sized ball for each chamber in the cylinder. If the round ball was the same size as the diameter of the chamber, there would be no ring shaved off as you ram it down.

Because you have to shave this ring out of the round ball, the lead must be soft enough for the loading lever which is attached underneath your barrel. If the lead is too hard, the loading lever will break at its weakest point before you ever manage to ram the round ball down into the cylinder.

How to Tell if Lead is Soft Enough for Black Powder Revolvers

Lead is soft enough for black powder revolvers when you can dent the lead round ball with nothing more than light to moderate pressure from your thumbnail.

If it takes a metallic tool to make a mark in the round ball, it’s too hard. If it takes extreme effort to make a dent in it with your thumbnail, then you are in that gray area and it is best to pass on the material that you have or use it in a musket or rifle.

If you have lead alloy that is too hard, you can also try melting it down and mix in what you know to be true, soft lead. It will still technically be an alloy, but you can “thin it out”, so to speak, and make the ratio greater favor of lead over the antimony and tin.

What Scrap Lead Can Be Used for Cap and Ball Revolvers

If you can still find a local tire place that will give you wheel weights then I wouldn’t stop collecting them even if they are too hard in their current form for your revolver. Like I mentioned above, you can always melt a few down with pure lead to still find an acceptable blend.

Soft Lead Sources for Black Powder Bullet Casting:

- Fishing sinkers and split shot

- Roof flashing

- Stained glass “lead came”

- Dental x-ray foils from the trays they put in your mouth

- range scrap from the inner lead of spent jacketed bullets (not hard cast)

If you find hard-cast bullets that are not jacketed (having a thin copper outer covering and soft lead core) then they will certainly be too hard for revolvers since they are a hard alloy.

If you find any spent range bullets and you’re not sure, just try taking a hammer to them on an anvil with light taps. Soft lead will easily flatten. Lead with too much antimony and tin will be very difficult to dent with the same amount of pressure.

Lead for Black Powder Revolvers Online

If you just can’t seem to find an appropriate source of lead, you can always purchase online.

At the time of this article, lead was selling for about $2.50 per lb (whether it’s worth it or not).

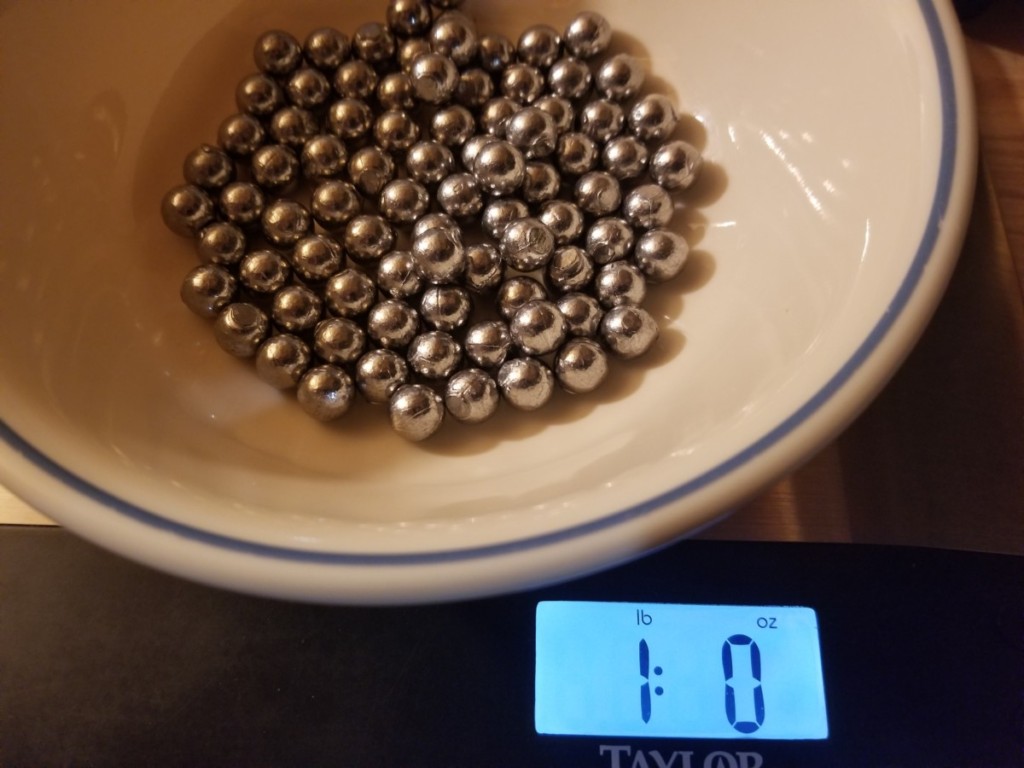

In my case, a pound of lead can get me about 85 round balls for my .36 caliber revolver with .38″ diameter round balls. It costs about $10.50 plus shipping to get 100 round balls.

Whether it’s Ebay, Rotometals.com, or Zipmetals.com, everything looks great when you add the lead to your cart until you hit the “calculate shipping” button when looking for scrap or ingots. Lead is heavy and the shipping reflects that. It seems the price at least doubles per pound depending on how much you get.

You’ll have to weigh the cost to benefit ratio for yourself to see if it’s worth it, or if you should be putting more effort into sourcing your own through a roofing company or simply sifting range scrap at your local gravel pit.

How many round balls can you cast per pound of lead?

If you want to see exactly how many round balls you can cast with a pound of lead, you can check out my article here are look at your particular caliber and the diameter of the round ball you’ll be casting. If your caliber is not listed, I provide the simple formula as well!

Thanks for checking out my post. I hope it helped you out on your black powder journey! I would be forever indebted if you find it interesting enough to share! Let’s keep building the hobby together!